By Wolf Richter, editor of Wolf Avenue. Initially revealed at Wolf Avenue.

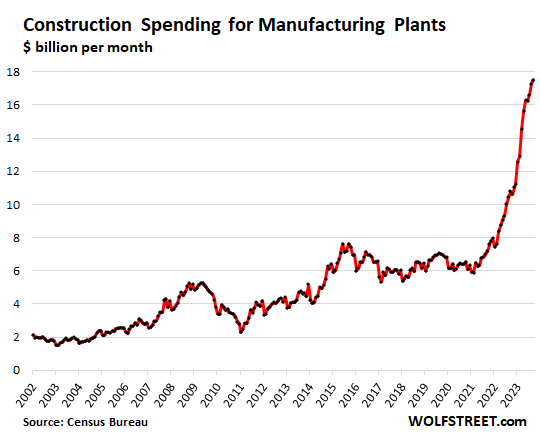

That is superb, and I’m undecided how lengthy it should final, however spending on building initiatives for manufacturing amenities within the US continues to spike in a historic method. In September, $17.5 billion, up by about 150% from the stagnation vary earlier than the pandemic.

For the primary 9 months of 2023, spending on manufacturing facility building jumped to $140 billion, up by 131% from $60 billion in the identical interval in 2019 and $59 billion in 2021.

Since January 2021, roughly when this increase began, spending has almost tripled. The speed of spending over the previous 5 months exceeds $200 billion annualized (not seasonally adjusted).

Manufacturing unit building bulletins proceed. For instance, simply this week, German industrial big Siemens introduced that it’s going to make investments $510 million within the US to construct factories: $150 million for a manufacturing facility in Texas to fabricate electrical gear for knowledge facilities; $220 million for a manufacturing facility in North Carolina to fabricate passenger rail automobiles and provide overhauls of railcars and locomotives (Siemens diesel-electric locomotives are utilized by Amtrak, Brightline, and different passenger railroads); and $140 million for factories in Texas and California to fabricate electrical merchandise.

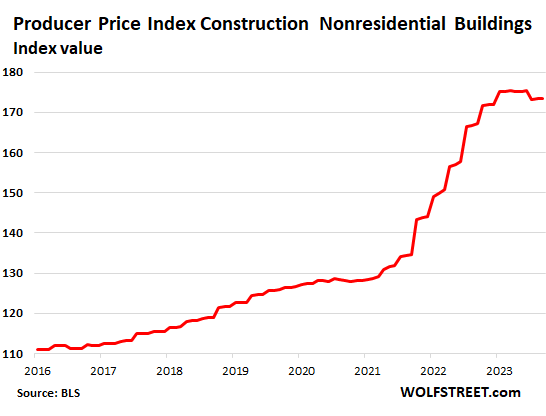

Half was inflation, however building prices have cooled. Over the 33 months since January 2021, the Producer Worth Index for nonresidential building has surged by 35%. Over the identical interval, spending on manufacturing facility building has spiked by 195%.

However the PPI has really declined slightly to date this 12 months. And the large year-over-year good points have been whittled down to simply 3.8% by September.

And there are lot extra {dollars} concerned. Building spending simply covers the buildings. Corporations put money into factories within the US to make high-value technologically superior merchandise corresponding to semiconductors and autos. They use extremely automated factories full of commercial robots. Then there may be different funding exercise to help the manufacturing facility, together with infrastructure building. The entire package deal counts as investments in GDP. What’s much more necessary for the economic system is what comes later when the manufacturing facility begins producing, creating its personal ecosystem of financial exercise.

Industrial robots value about the identical within the US as in China. The price of labor continues to be very totally different. And different prices are totally different. However on the plus facet are shorter lead occasions, much less transportation expense, much less geopolitical uncertainty, extra management over IP, and so forth.

Taxpayers are shanghaied into subsidizing manufacturing facility building on the native, state, and federal stage, and this has been happening ceaselessly.

What’s new is the disruption skilled by world provide chains – they virtually all run by China – throughout the pandemic that led to shortages of every kind. As well as, there are every kind of frictions, disputes, uncertainties, and tariffs between the US and China. US producers must toe the road in China. Even Musk, an enormous defender of free speech, is mouse-quiet in China about free speech. His gigafactory in Shanghai is value much more than free speech, that’s for certain.

What’s additionally new are enormous federal subsidies for semiconductor manufacturing vegetation, EV battery vegetation, and EV meeting vegetation, and subsidies for purchases of EVs that conform to geographic manufacturing limitations. Makers of pc, digital, and electrical gear are additionally massive drivers behind the surge of manufacturing facility building, in accordance with an evaluation by the Treasury Division.

However wait… the development increase took off within the spring of 2021. Over a 12 months later, in July 2022, Congresses handed a package deal of subsidies for choose manufacturing industries, corresponding to semiconductor makers (as much as $52 billion). However building spending doesn’t instantly occur when the regulation is handed. The federal government takes its time really handing out the cash. And these massive building initiatives themselves take some time time earlier than building may even begin. So a portion of these subsidies for manufacturing facility building are doubtless to supply additional gasoline going ahead.

By output, the US is the second largest manufacturing nation behind China, and has a better share of worldwide manufacturing than the following three mixed (Germany, Japan, and India). Nearly all of motor autos offered within the US are assembled in factories within the US. All main overseas manufacturers have meeting vegetation within the US. Tesla makes autos within the US, together with for export.

However the US, as the most important economic system on the planet, has fallen far behind China in manufacturing, whereas many sectors have turn into depending on manufacturing in China. And points throughout the pandemic, together with the semiconductor shortages, have been a brutal wakeup name.